Comparison of Flue Gas DeNOx SCR and SNCR Technology

Flue gas DeNOx (Nitrogen Oxides) technologies play a crucial role in reducing harmful emissions from industrial processes. Two widely used methods for NOx reduction are SCR (Selective Catalytic Reduction) and SNCR (Selective Non-Catalytic Reduction) technologies.

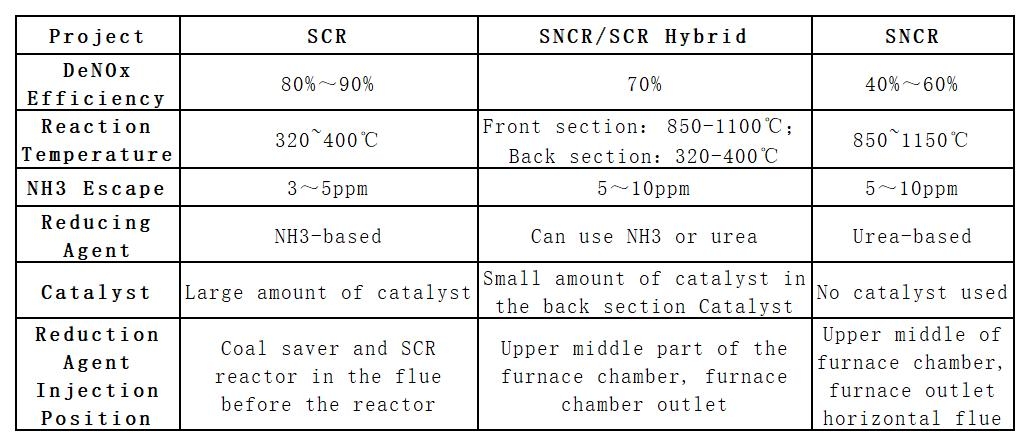

Denitrification process

There are several reasons why we would recommend SCR (Selective Catalytic Reduction) technology over SNCR (Selective Non-Catalytic Reduction) technology for certain applications:

* Higher NOx Removal Efficiency: SCR technology offers higher NOx removal efficiency compared to SNCR. SCR systems can achieve up to 90% or higher NOx reduction rates, making them more suitable for industries with stringent emissions regulations or those aiming for substantial emissions reductions.

* Consistent Performance Across a Wide Range of Conditions: SCR technology exhibits stable and reliable performance across a wide range of flue gas conditions, including variations in temperature, flow rate, and pollutant concentrations. It ensures consistent and effective NOx reduction, regardless of fluctuations in process operations.

* Lower Ammonia Slip: SCR technology allows for precise control of the ammonia-to-NOx ratio, resulting in lower ammonia slip. This is crucial to comply with strict environmental regulations and minimize the release of unreacted ammonia into the atmosphere, which can have its own environmental impact.

* Compatibility with Various Fuels: SCR technology is compatible with a wide range of fuels, including coal, natural gas, oil, biomass, and more. This versatility allows industries using different fuel types to implement SCR systems, providing a flexible and effective solution for diverse applications.

* Long-Term Reliability and Proven Track Record: SCR technology has been extensively researched, developed, and deployed in various industries for many years. Its effectiveness and reliability have been proven through practical applications, making it a trusted choice for businesses seeking long-term and sustainable NOx reduction solutions.

* Potential for Energy Savings: Compared to SNCR, SCR technology can operate at lower temperatures, resulting in potential energy savings. The lower temperature operation of SCR systems can contribute to overall process efficiency and reduced energy consumption, leading to cost savings in the long run.

While SNCR technology has its own advantages, such as simplicity and lower upfront costs, SCR technology offers higher NOx removal efficiency, greater reliability, and wider operational flexibility. Ultimately, the choice between SCR and SNCR depends on the specific requirements, emission regulations, and characteristics of the industrial process in question.

As the largest manufacturer of honeycomb SCR catalysts in China, Yuanchen offers comprehensive services including catalyst design, selection recommendations, sample testing, production, delivery, and regular post-sales follow-up. Choose Yuanchen for your flue gas treatment efficiency!

Leave us the questions you encounter when choosing honeycomb SCR catalysts, and we will arrange professional technical personnel to provide you with free consultation services.

↓ ↓ ↓ ↓ ↓