Is high efficiency filter leakage rate test ≤0.01% necessary?

Is high efficiency filter leakage rate test: ≤0.01% necessary?

What is the acceptance criterion for HEPA filters?

Most test standards regarding the acceptance criterion for HEPA filter leak rates state that the acceptable leak limit is ultimately determined by the customer and supplier. However, for many applications using HEPA filters or different levels of cleanroom, most adopt a scan test leak criterion of ≤0.01%. Although 0.01% leak rates have been used historically and their origins are related to the accuracy of early photometer test equipment, using a 0.01% leak rate criterion as the acceptance criterion without a scientific and risk-based assessment will lead to problems associated with leak testing and may result in significant operating costs if an over-limit or failure is found in a low-risk area. Filters are not 100% retaining and particles near the MPPS are expected to penetrate the filter partially or entirely. When using lower-level HEPA filters, the factory-performed acceptable leak rate criterion for particles at or near the MPPS may be equal to or greater than the acceptance criterion for field leak rate testing, and testing acceptance criteria becomes more controversial and difficult. This is especially true in areas where leaks may occur. Therefore, when purchasing filters, it is important to consider the filter rating and how it will be tested after installation to avoid unnecessary field test failures.

ISO 14644-3 [33] provides guidance on how to implement alternative leakage criteria. In a risk-based approach, the ideal acceptance criterion is one that reflects the efficiency of the filter used or the cleanliness of the room being tested. ISO 14644-3 uses the factory filter efficiency rating as the basis for negotiating the acceptance criterion. The leakage acceptance criteria for photometric leak testing and particle counter-based leak testing should be the same because the theory and methodology behind both methods are the same. If performed properly, leak tests using a photometer and a particle counter will give the same leak rate results (Meek et al., 2011 [121]).

If the detected leakage exceeds 0.01% of the upstream concentration, it is generally considered that the leakage rate exceeds the maximum permissible standard.

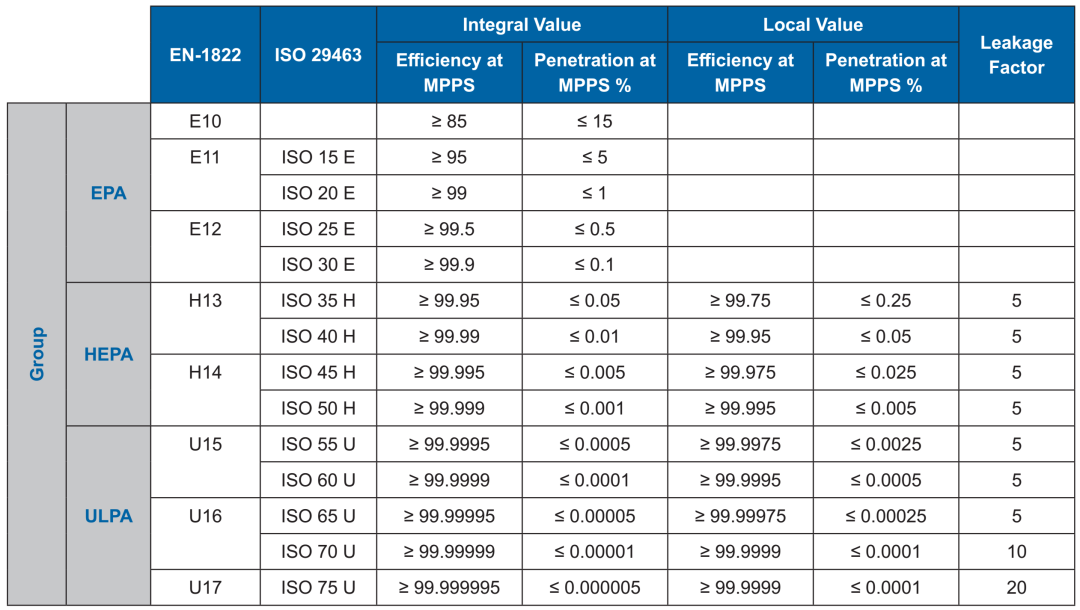

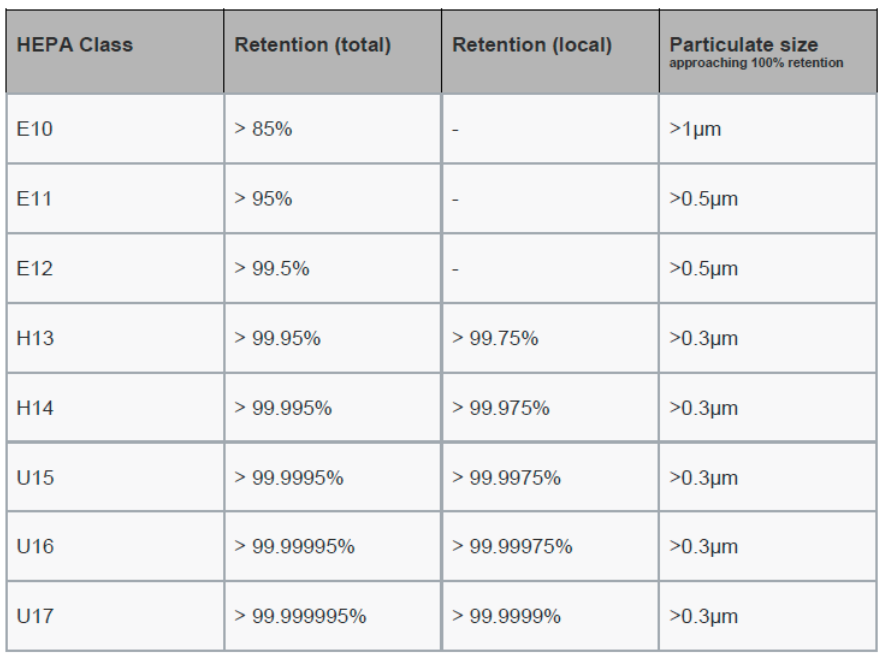

However, for filter systems with an overall efficiency MPPS ≥ 99.95% and less than 99,995% (such as H13 filters), the acceptance standard is 0.1%. If a filter system with an overall efficiency of less than 99.95% MPPS is to be tested, a different acceptance standard is required, depending on the agreement between the customer and the supplier.

Importance of High Efficiency Particulate Air Filters (HEPA) and Leak Detection Methods and Standards

Cleanrooms require air filters to prevent contaminants from entering the cleanroom through their HVAC systems. Cleanrooms are controlled environments where the control of temperature/humidity, pressure, and particulate matter is critical for optimal operational performance. Cleanrooms are designed based on the cleanliness required for a specific process. In the semiconductor industry where microchip manufacturing is performed, air filtration has a higher efficiency because microchips are very sensitive to particles, especially small particles that get wedged between the conductive circuits on the wafers when the wafers are handled.

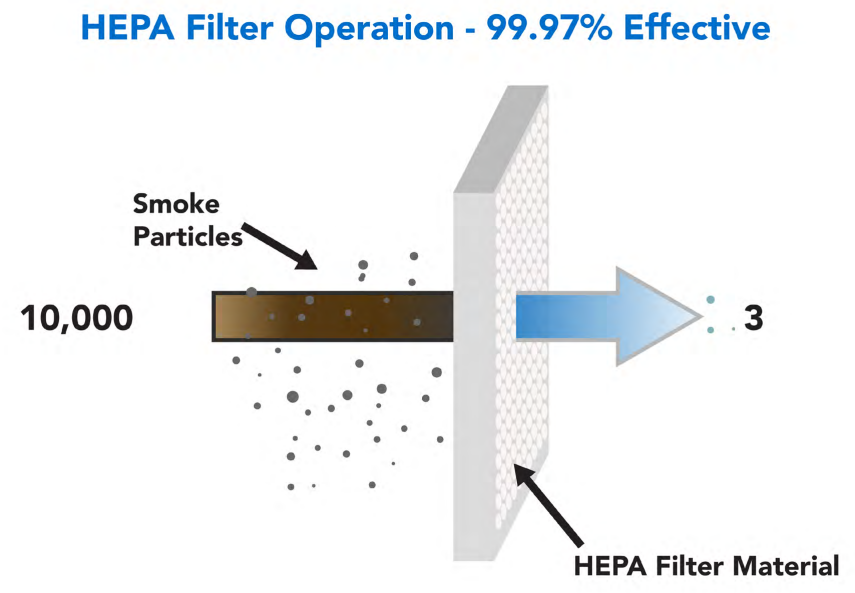

High Efficiency Particulate Air Filters (HEPA), these filters are very effective in contamination control. They filter particles as small as 0.3 microns and are widely used in pharmaceutical facilities. ULPA (Ultra High Particulate Air Filters) filter particles below 0.12 microns and are widely used in semiconductor equipment.

Importance of Filters in Cleanrooms

Managing Contamination Control in Cleanrooms through Several Activities High Efficiency Particulate Air Filters or UPLA Filters play a vital role in cleanrooms. High Efficiency Particulate Air (HEPA) filters must be as efficient as 99.97% penetrating particles, 0.3 microns. This efficiency rating is given by the U.S. Department of Energy to qualify as a true HEPA filter.

HEPA Filter Specifications

As defined by the U.S. Department of Energy (DOE) standards adopted by most U.S. industries, the minimum resistance or pressure drop a HEPA filter presents to airflow is usually specified at 300 Pascals (0.044 psi) across the filter diameter.

Specifications used by the European Union: European Standard EN 1822-1:2009 defines categories of HEPA filters by their retention at a given most penetrating particle size (MPPS).

According to GMP, filters must be leak-free. This is verified by qualification and periodic leak testing according to ISO 14644-3. Recommended Practices for HEPA Filter Construction, Performance, Labeling, and Certification are maintained by the Institute of Environmental Sciences and Underwriters Laboratories (UL). Key requirements include:

■ IEST-RP-C021 “Testing HEPA and ULPA Media, which governs requirements for filter media

■ IEST-RP-CC001 “High Efficiency Particulate Air Filters and Ultraparticulate Air Filters”, governs overall filter construction and labeling requirements

■ IEST-RP-C034 “HEPA and ULPA Filter Leak Testing, for HEPA and UL PA filter penetration (leakage) testing

■ Testing and certification to UL900 flammability requirements

■ American Standard MIL-STD-282

Other testing standards include:

■ ISO 14644-3 Test Method – Qualified Persons Used During Installed Filter Leakage Testing

■ ISO 29463 (2017) – High Efficiency Filters and Filter Media for Removal of Airborne Particles

■ ISO 16890 (2017) – Air Filters for General Ventilation

■ PIC/s PI 032-2 GMP Guide

■ EN1822 used by HEPA/UPA filter manufacturers

High efficiency filter testing is a key technology and an important step to ensure a safe working environment and improve air quality. Filter test data is more effective in formulating a more scientific maintenance and replacement plan for customers.

KLC high efficiency filter testing program:

1. Smoke test

During the testing process, we use advanced instruments and technology to accurately measure the filter's capture rate of particles of different sizes and control a variety of environmental variables.

2. MPPS test

Comprehensively analyze the filter's performance under high flow conditions to ensure it can effectively maintain good air quality and system efficiency in actual use.

3. DOP Test

Used to verify the performance of filters in capturing fine particles of dirt, especially in fields such as pharmaceuticals, electronics and aviation where air quality is extremely high. This test uses DOP aerosol to accurately simulate the filtering effect of fine particles in actual working environments.