1. Environmentally friendly materials: the first guarantee for children's safety

With the increasing awareness of environmental protection, more and more parents are beginning to pay attention to the safety and environmental friendliness of materials when choosing children's toys. Especially magnetic building block toys, as a common choice for children to play, their materials must not only meet child safety standards, but also be environmentally friendly.

Our magnetic building blocks series are made of ABS plastic, which is not only lightweight and durable, but also non-toxic and harmless, fully complying with national and international safety standards. During the production process, we strictly follow environmentally friendly manufacturing processes and avoid the use of any harmful substances to ensure that each toy can provide children with a safe gaming experience.

In addition, our magnetic toys also adopt environmentally friendly coatings, which are non-toxic and have good anti-wear performance, ensuring that the toys will not produce harmful substances during long-term use, while also being able to withstand children's active operations.

2. Magnetic toys: stimulate children's creativity and imagination

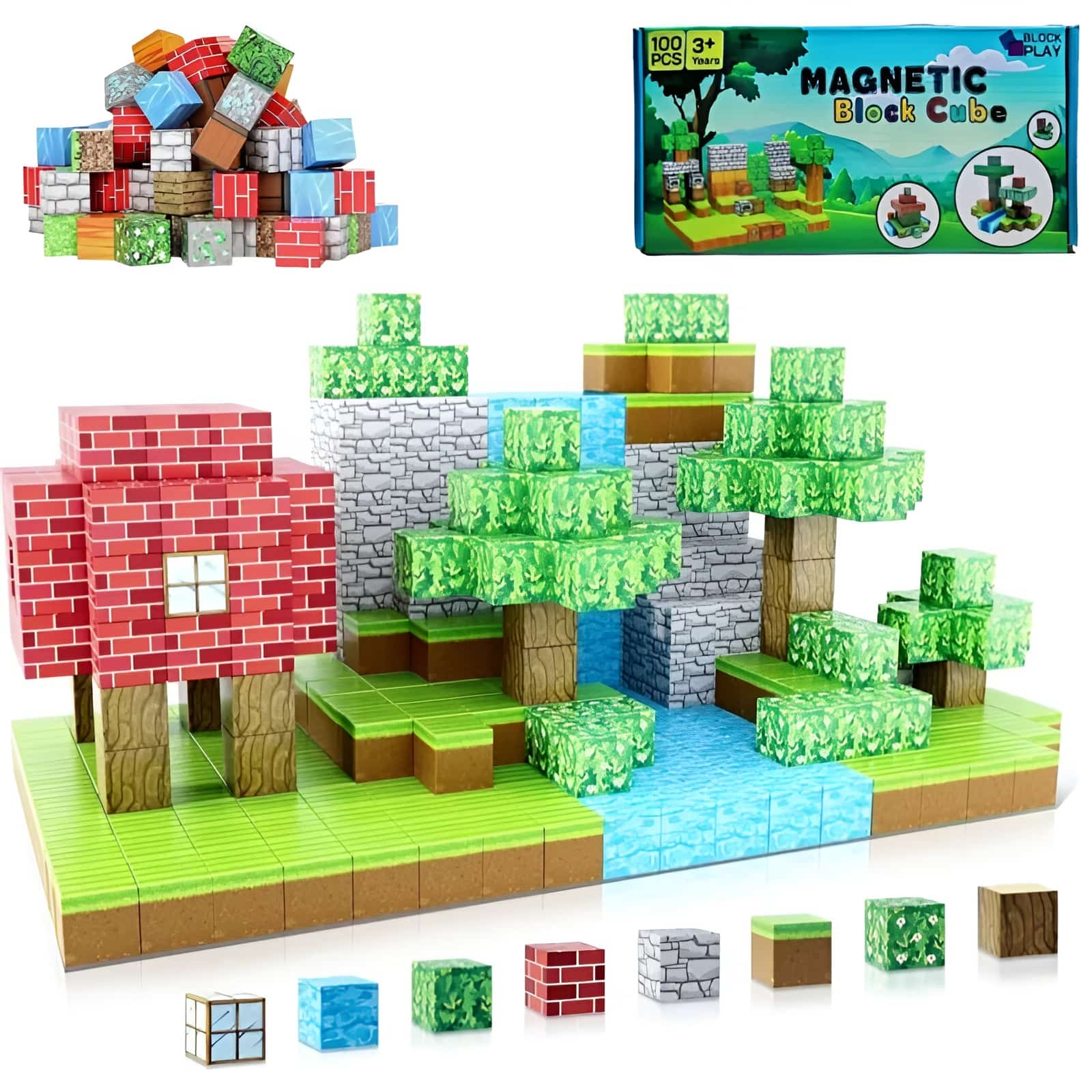

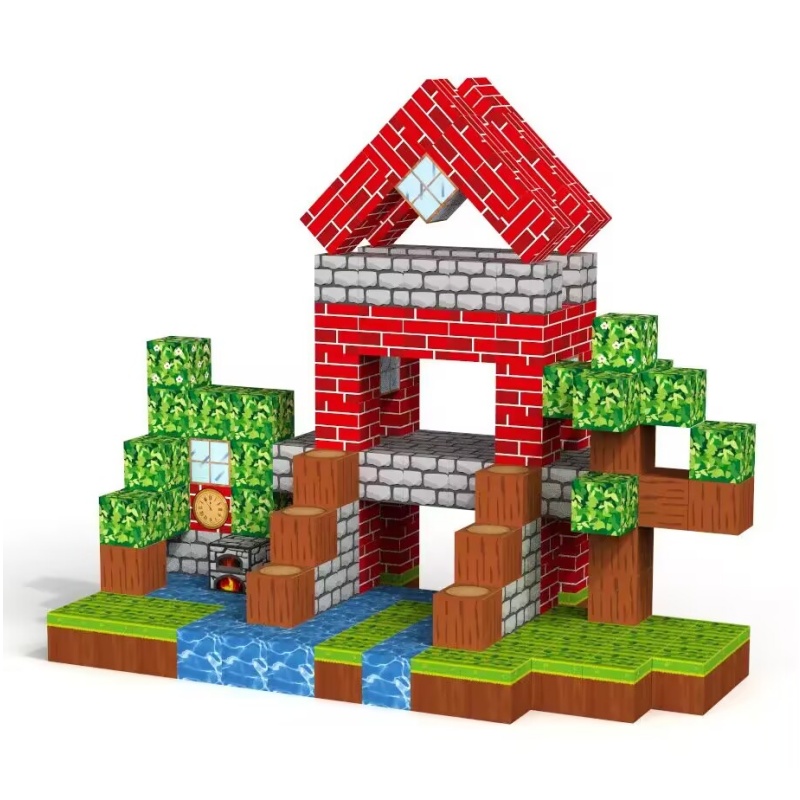

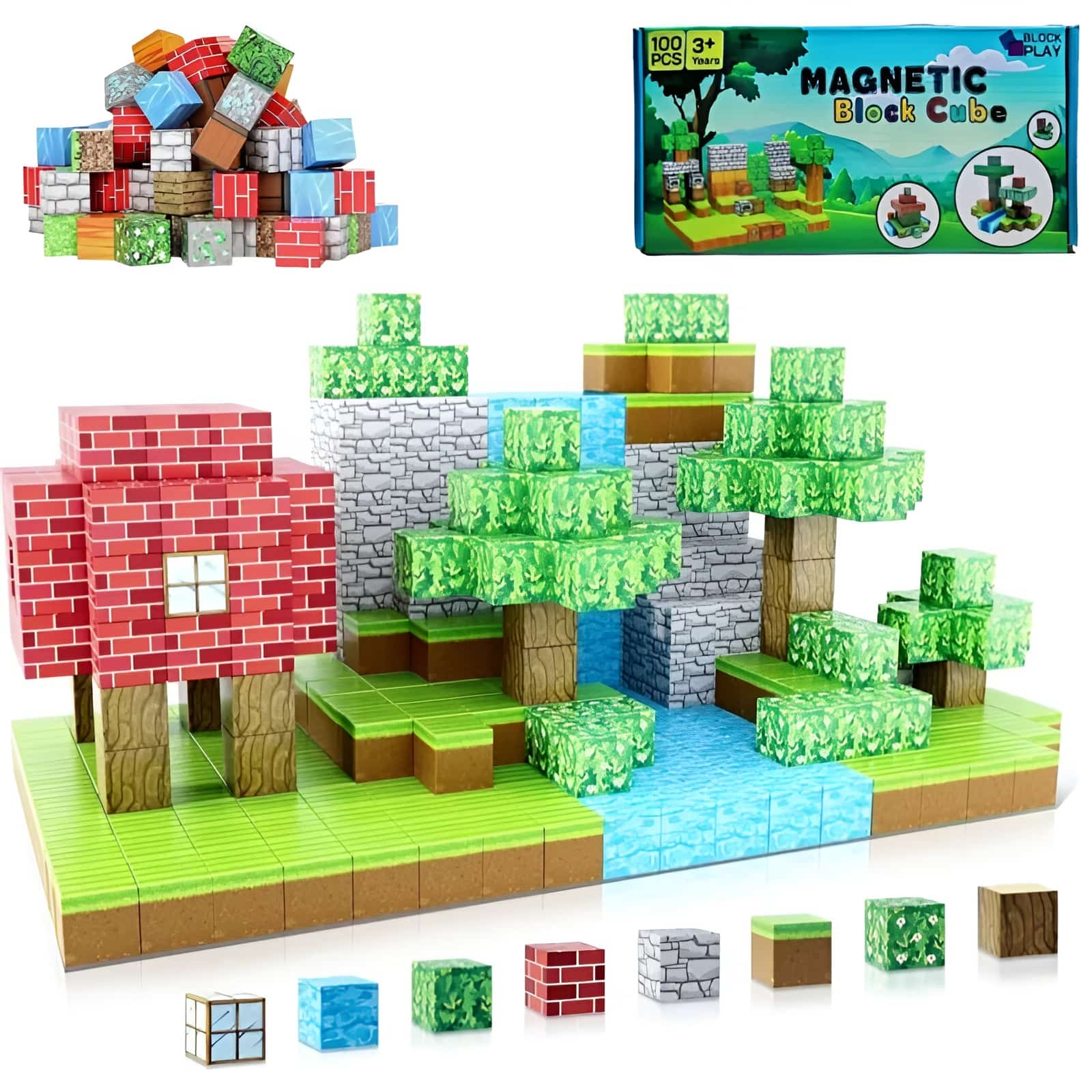

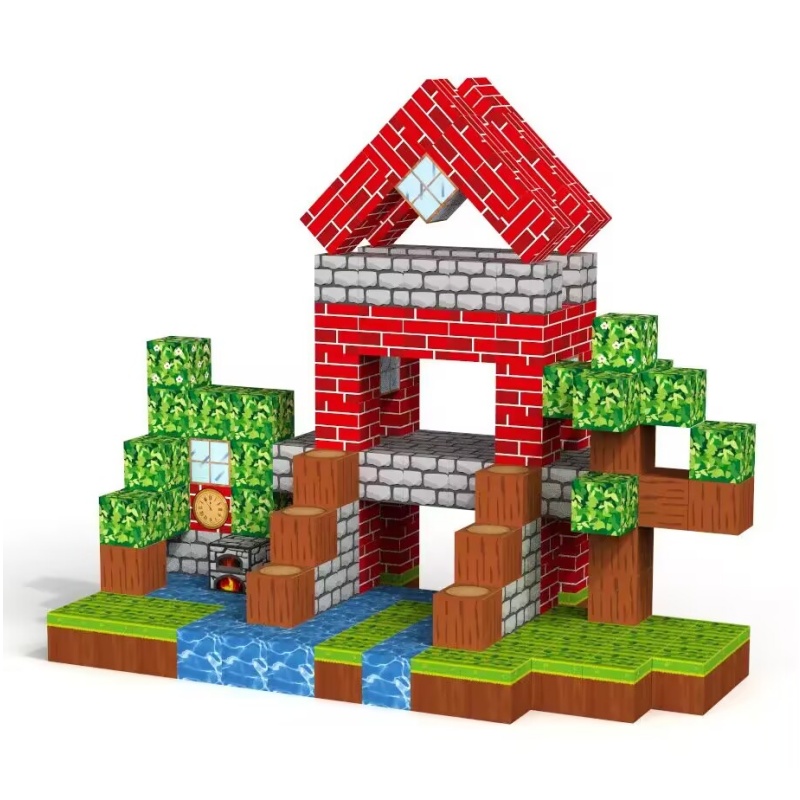

As children grow up, creativity and imagination are essential for the development of intelligence. Traditional toys are often limited to a single way of playing, while customized magnetic toys, with their unique physical properties, can provide unlimited combinations and ways of playing, thus stimulating children's creative potential. Our magnetic building block series is especially suitable for children over 3 years old. Each magnetic building block has a strong magnetic force, allowing children to easily combine the building blocks into various shapes and structures.

3. Safety standards: a safe choice for parents

When parents buy magnetic toys, safety is often their top concern, especially for younger children, how to prevent them from accidentally swallowing magnets or other small parts is very important. Therefore, all our magnetic toys are produced in strict accordance with national safety standards and have passed multiple safety certifications to ensure that every child can use them in a safe environment.

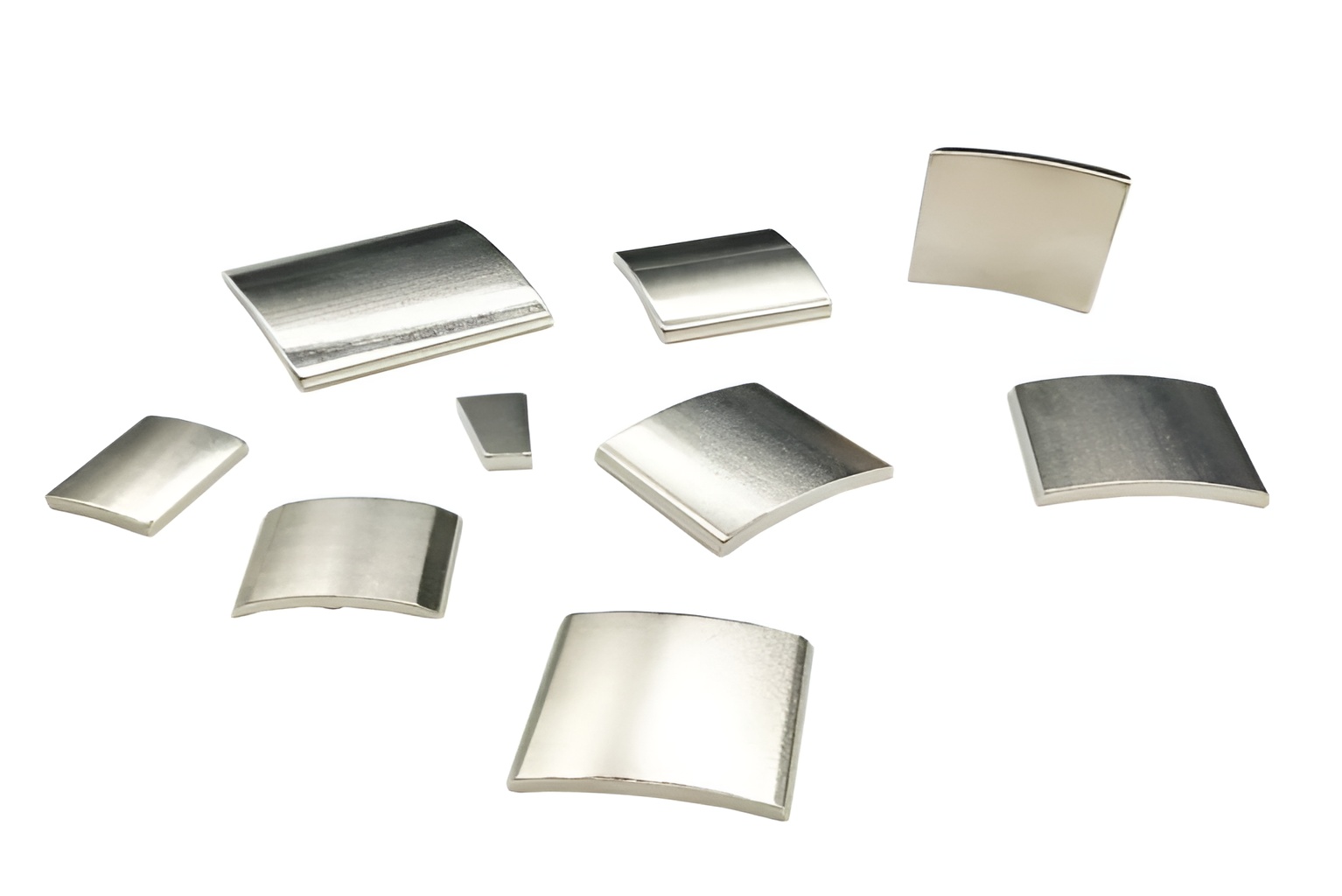

✱Safe Magnetic Design: Our magnetic building blocks are designed with low-intensity magnetic force, so even if children accidentally touch the magnets while playing, it is not easy to cause danger. At the same time, the connection method of the magnetic building blocks is carefully designed to ensure that no small parts will come loose and avoid the risk of accidental swallowing.

✱ No sharp edges: All magnetic building blocks and toys are finely polished to ensure that there are no sharp edges and will not hurt children's skin.

✱ Age-appropriate design: Our magnetic building blocks are specially designed for children aged 3 and above, in line with the children's intellectual development stage, ensuring that they can bring fun and promote cognitive ability.

4. Green and sustainable development: Future responsibility

As the global environmental protection trend continues to advance, more and more brands are beginning to incorporate the concept of green and sustainable development into product design. Our magnetic toys use recyclable materials in the production process and optimize the manufacturing process to reduce energy consumption in the production process. In addition, we also ensure the durability of each product through strict quality control, reducing the waste caused by consumers replacing toys.

In general, the combination of environmentally friendly materials and magnetic toys not only ensures the safety and durability of the toys, but also stimulates children's creativity and helps them learn and grow in play. Choosing our magnetic toys is not only choosing an innovative and environmentally friendly way of entertainment, but also providing a brand new tool for children's intellectual development and creative cultivation.