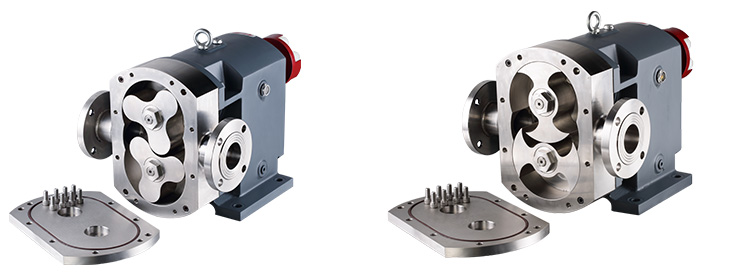

Rotary lobe pump applications and advantages

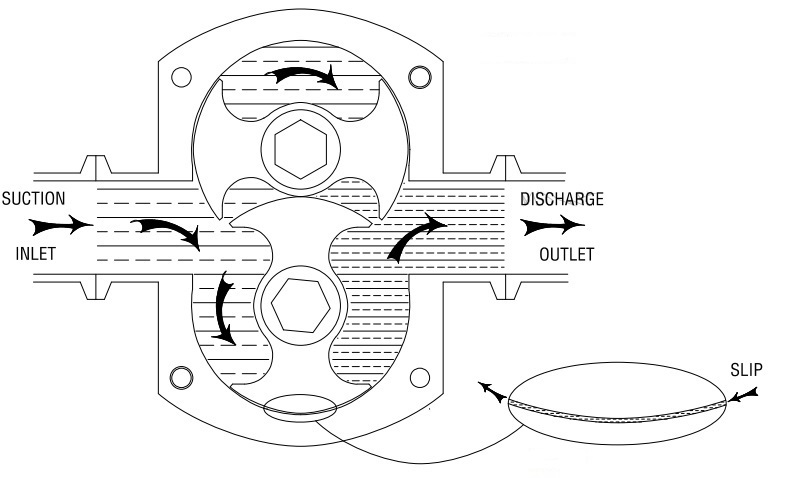

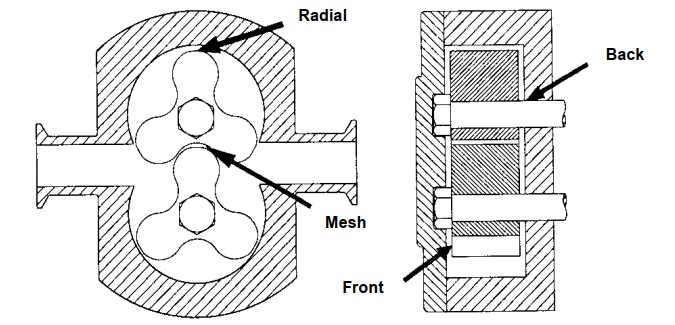

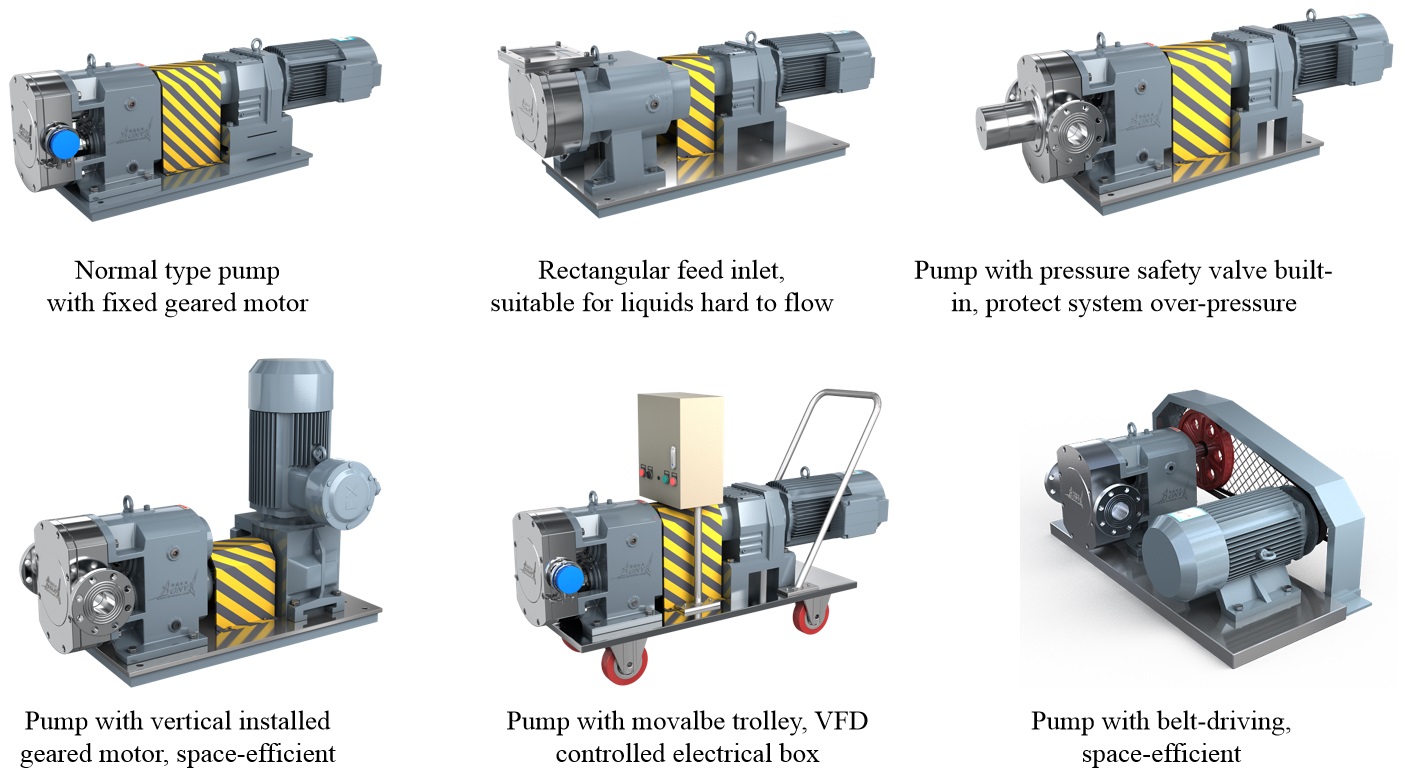

Rotary lobe pumps types

Applications of rotary lobe pumps

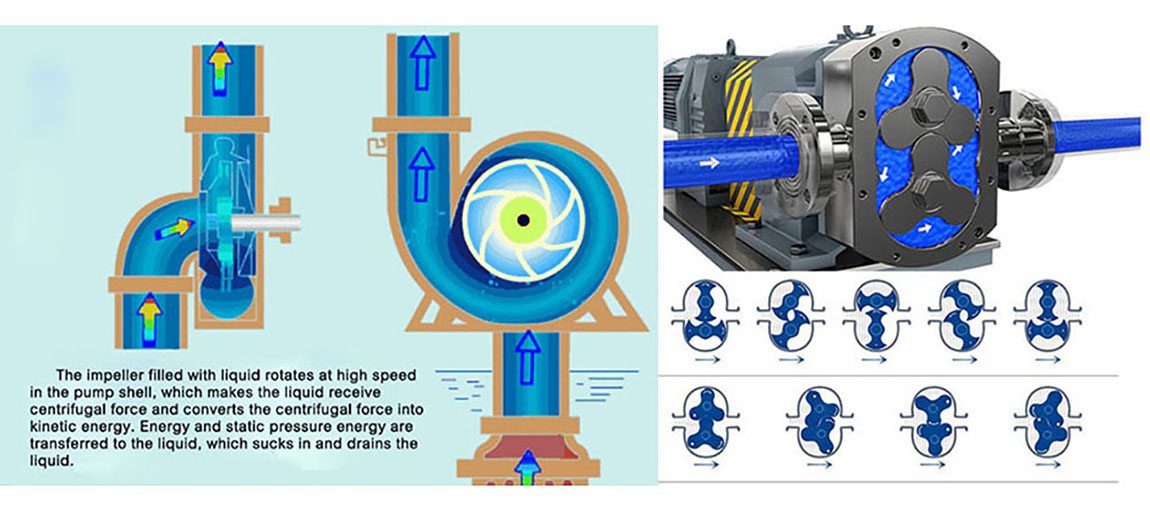

Advantages of rotary lobe pumps

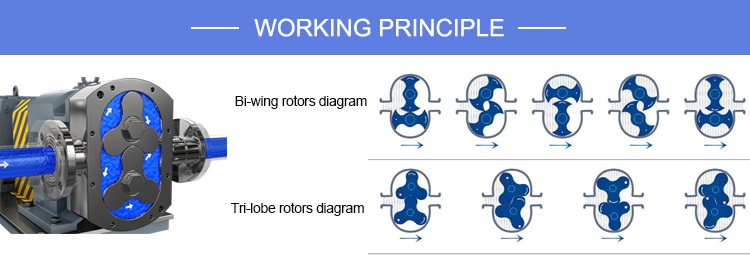

Types of rotary lobe pumps

Rotary Lobe pump manufacturers mainly divide their pumps into two types, food sanitary grade lobe pumps and industrial chemical grade lobe pumps.

Applications of lobe pumps

Food sanitary grade lobe pumps include, but limited to:

- Foods: Chocolate, concentrated milk, yogurt, honey, syrup, cane sugar, tomato juice, concentrated juice, jam, ice cream, milk, yeast slurry, meat slurry, jelly, condiment, lees, soybean protein, flour slurry, etc.

- Pharmaceuticals: Ointments, extract, medicine latex, pill paste, syrup, health care products, drugs,vaccine etc.

Industrial chemical grade lobe pumps include, but are not limited to:

- Consumer chemicals: AES, LAS, AOS, K12, glycerol, fatty alcohol, bathing shampoo, skin cream, shampoo, detergent liquid, toothpaste soap, washing powder slurry, etc.

- Refined chemicals: Dyes stuffs, pigments, all kinds of pulp, chemical additives, adhesives, silicone oil, leather oil, a variety of colloidal materials, etc.

- Coating: Paint, dope, printing ink, insulating paint, resin, additives and assistants, organic solvent, etc.

- Chemical fiber: Pectic slurry, PVA, spandex slurry, vinylon slurry, Acrylic slurry, polyester slice, terylence, polypropylene fiber, rayon, functional fiber, etc.

- Pulp & Paper: Polyacrylamide, calcium carbonate, starch paste, carboxyl poly, starch paste, rosin size, paper pulp, filling dry strength agent, wet strengthen agent, sizing agent, filtering agent, anti foaming agent, spreading, water treatment chemicals, etc.

Below is the table for applications

|

Alcohol |

Coffee liquor |

Glycerin |

Mousse |

Sorbitol syrup |

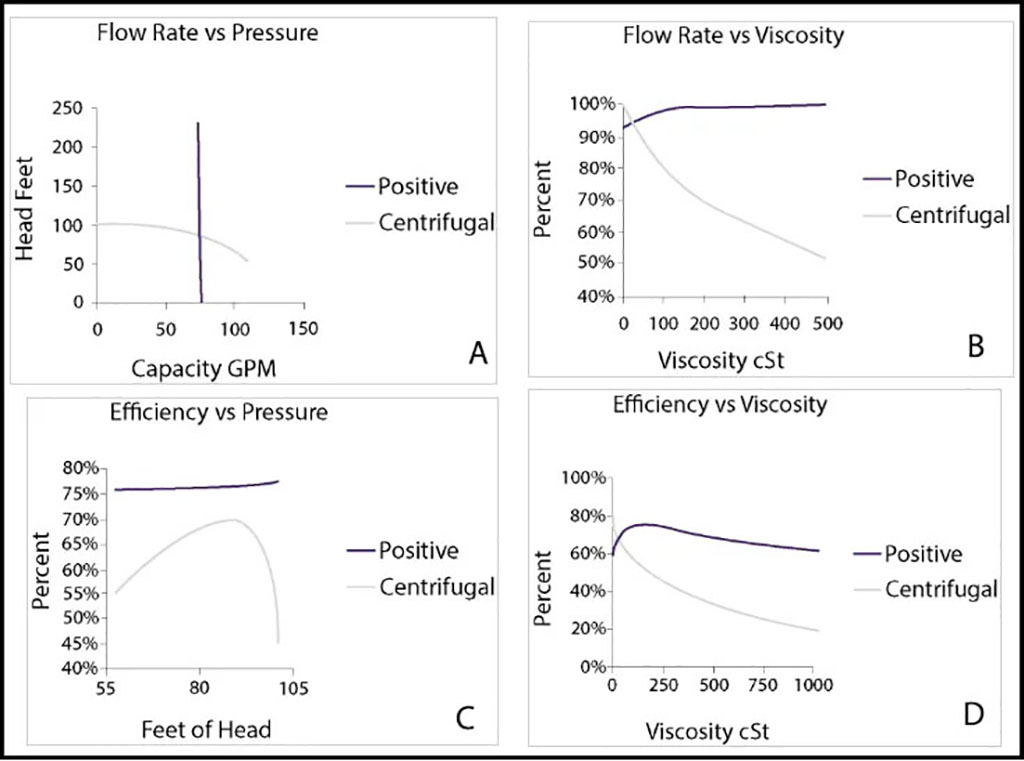

Advantages of rotary lobe pumps

- High efficiency,energy-saving.

- Non-pulsating discharge, stable working.

- High temperature of 220 C degree handling (with FFKM o-rings).

- Capable of pumping mixture of gas, fluid and solid materials.

- No metal-to-metalrotorscontact,no friction andlong service life.

- Simpleand compact structure, easy maintenance and CIP/SIP capabilities

- Capable to pump the viscous material ≤1,000,000cp and pulp with the solid upto 70%.

- When equipped with frequency converter,flow rate can be adjusted and used asa metering pump.