Principle of Various NDT Methods

I. What Is Eddy Current Testing

Eddy-current testing (also commonly seen as eddy current testing and ECT) is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials.

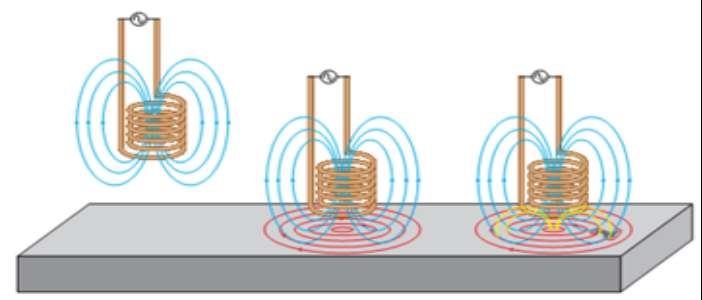

ECT principle

In its most basic form - the single-element ECT probe - a coil of conductive wire is excited with an alternating electrical current. This wire coil produces an alternating magnetic field around itself in the direction ascertained by the right-hand rule. The magnetic field oscillates at the same frequency as the current running through the coil. When the coil approaches a conductive material, currents opposed to the ones in the coil are induced in the material - eddy currents.

Variations in the electrical conductivity and magnetic permeability of the test object, and the presence of defects causes a change in eddy current and a corresponding change in phase and amplitude that can be detected by measuring the impedance changes in the coil, which is a telltale sign of the presence of defects. This is the basis of standard (pancake coil) ECT.

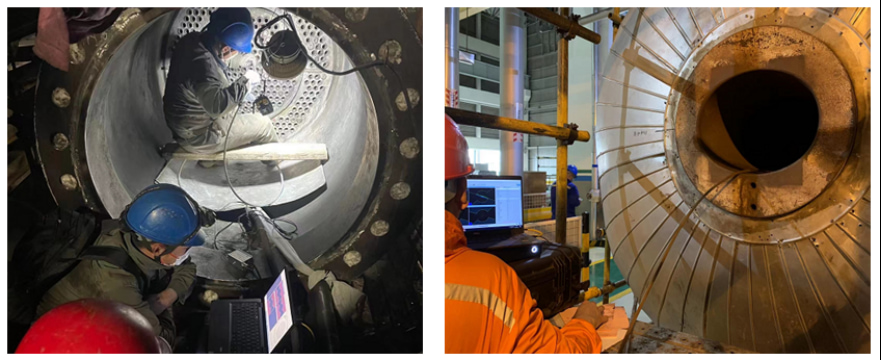

ECT has a very wide range of applications, including crack inspection, weld inspection, heat exchanger tube inspection, auto parts inspection, heat treatment inspection, material sorting and so on. There are also physical limits to generating eddy currents and depth of penetration (skin depth).

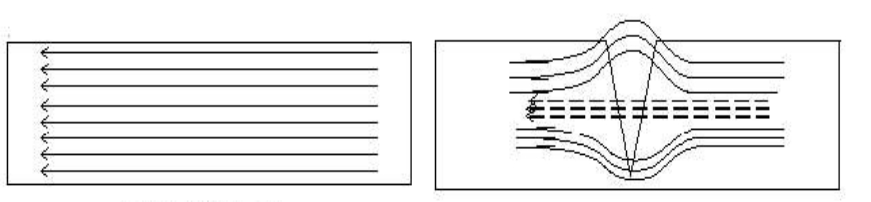

Skin effect

Skin effect is the tendency of an alternating electric current (AC) to become distributed within a conductor such that the current density is largest near the surface of the conductor, and decreases with greater depths in the conductor. The electric current flows mainly at the "skin" of the conductor, between the outer surface and a level called the skin depth. The skin effect causes the effective resistance of the conductor to increase at higher frequencies where the skin depth is smaller, thus reducing the effective cross-section of the conductor. The skin effect is due to opposing eddy currents induced by the changing magnetic field resulting from the alternating current.

Skin depth

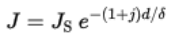

The AC current density J in a conductor decreases exponentially from its value at the surface JS according to the depth d from the surface, as follows:

where δ is called the skin depth. The skin depth is thus defined as the depth below the surface of the conductor at which the current density has fallen to 1/e (about 0.37) of JS.

The current density which is smaller than 1/e (about 0.37) of JS is too weak to test. So eddy current testing is used for surface and subsurface inspection.

II. What Is Magnetic Flux Leakage

Magnetic flux leakage (TFI or Transverse Field Inspection technology) is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks. The basic principle is that a powerful magnet is used to magnetize the steel. At areas where there is corrosion or missing metal, the magnetic field "leaks" from the steel. In an MFL (or Magnetic Flux Leakage) tool, a magnetic detector is placed between the poles of the magnet to detect the leakage field. Analysts interpret the chart recording of the leakage field to identify damaged areas and to estimate the depth of metal loss.

III. What Is Low Frequency Testing

Low frequency testing is a method between eddy current and magnetic flux leakage. Eddy current is mainly for surface and subsurface crack and magnetic flux leakage is for corrosion of thick material. Low frequency can test more thick material than eddy current and it doesn’t need to magnetize the material like MFL. So LFT can be used to detect big corrosion for thick material, of course the testing sensitivity is not as high as eddy current and magnetic flux leakage.

IV. What Is Metal Magnetic Memory

Metal magnetic memory testing is to determine the stress concentration area. Experiment proves that under the action of the alternative loading, the normalization phenomenon of the magnetic domain occurs at the places containing defects and inclusions in in-service ferromagnetic components, and leakage magnetic field arises on it. At the places of defects or internal stress relative concentration the metal magnetic conductivity is in possession of minimum value, and the tangent component of its magnetic field is in possession of maximum value, and therefore the sign of the normal component is changed and its value is zero. The stress concentration areas can be located by detecting the normal component of leakage magnetic field on the surface.