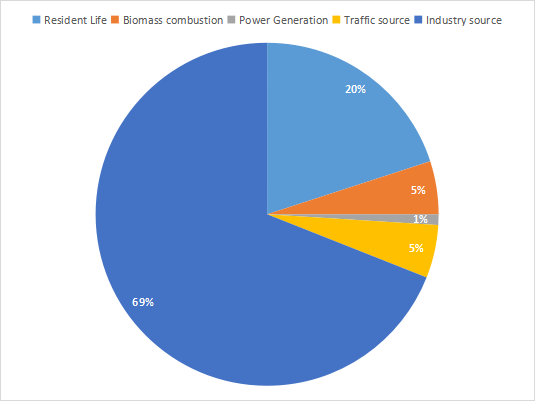

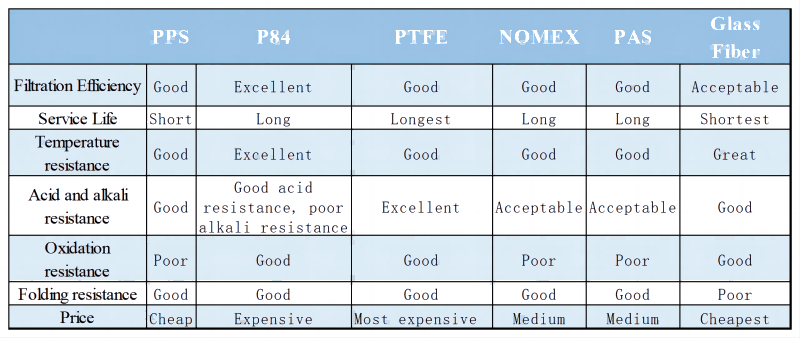

At present, industrial pollution is the largest source of PM2.5 in China, with cement manufacturing, coal-fired power plants, and steel metallurgy being the 3 major culprits among industrial pollution sources. Therefore, industrial filtering cannot be ignored in the management of PM2.5.

Sources of PM2.5

(Source: IPE)

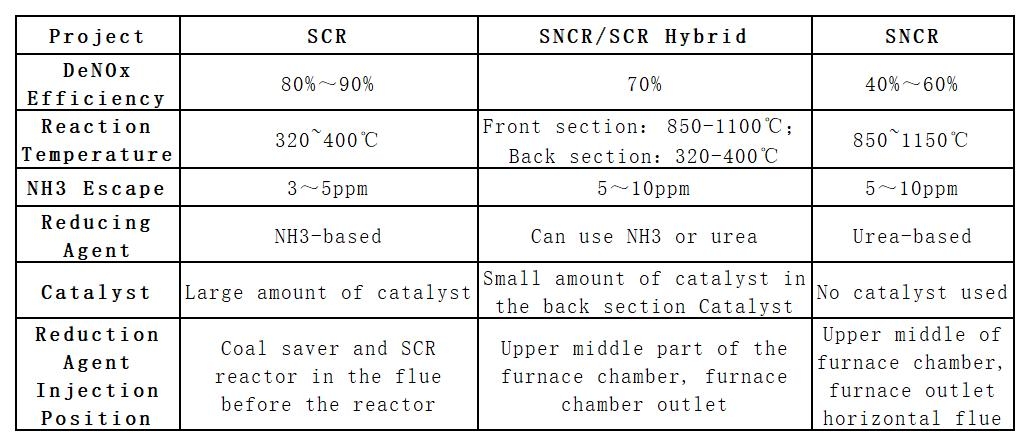

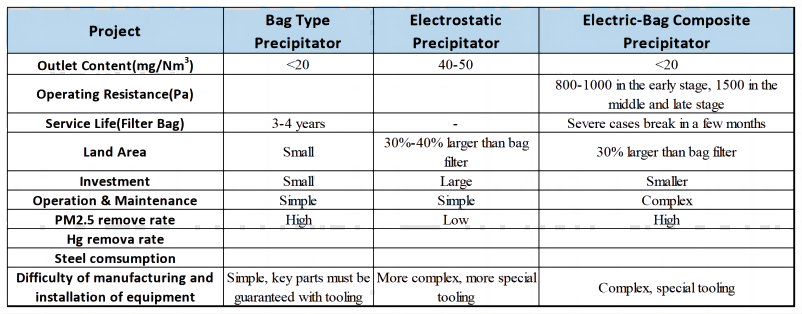

However, industrial filtering is not an easy task, because industrial fumes are hot and often contain acidic and alkaline gases, which require high requirements for the technology and materials used for industrial filtering. At present, there are two mainstream technologies for industrial dust removal, namely electrostatic precipitator and bag type precipitator. Based on these two, electric bag composite precipitator is derived.

Comparison of Economic Performance of Three Dust Collector Technologies

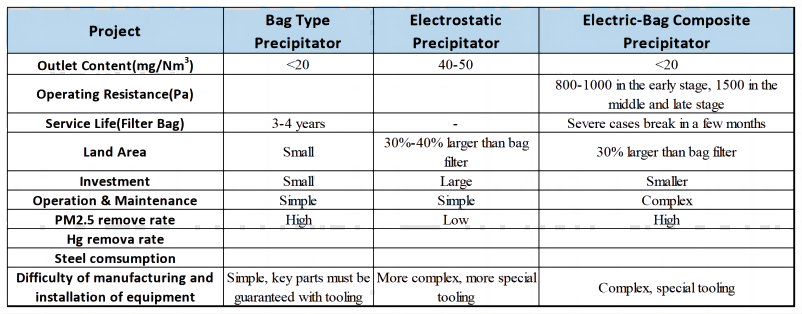

Bag Filter - The mainstream technology for industrial dust control: Currently, electrostatic precipitator technology in China has reached the stage of mature application, bag filter technology is in a period of rapid development. However, as the national requirements for controlling industrial flue gas pollution continue to improve, electrostatic precipitator technology alone cannot fully meet the requirements. The use of bag filter technology and electrostatic bag composite dust collectors as replacements for electrostatic precipitator technology has become mainstream.

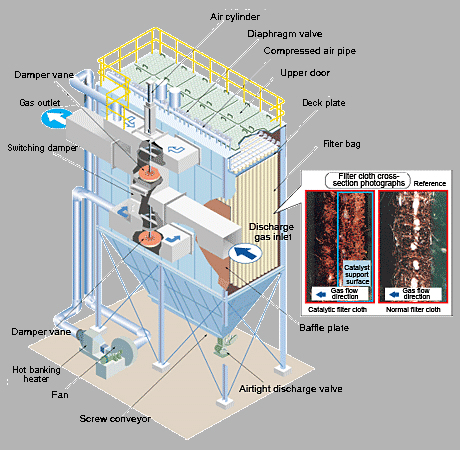

Mechanism of bag filters: Special fibers are used to make filter bags, and the dusty gas is injected into the bags, where the dust is filtered and captured. The filtering effect depends on the quality of the filter bags.

Structure of Bag Filter

(Source: Hitachi Plant Construction, Ltd. 56 )

You can also directly consult our sales engineers for free consultation services regarding your dust collection and denitrification projects.

↓ ↓ ↓ ↓ ↓

Contact us now!

High temperature Filter Material - The core material of bag filters

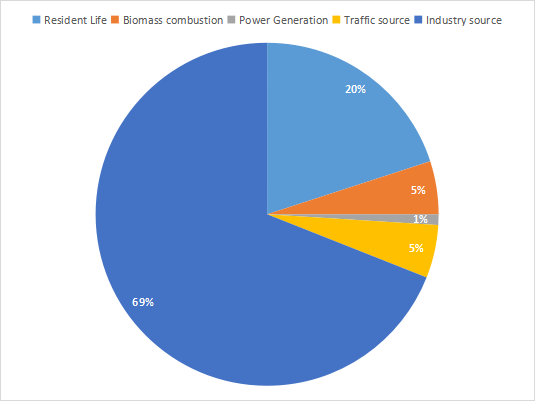

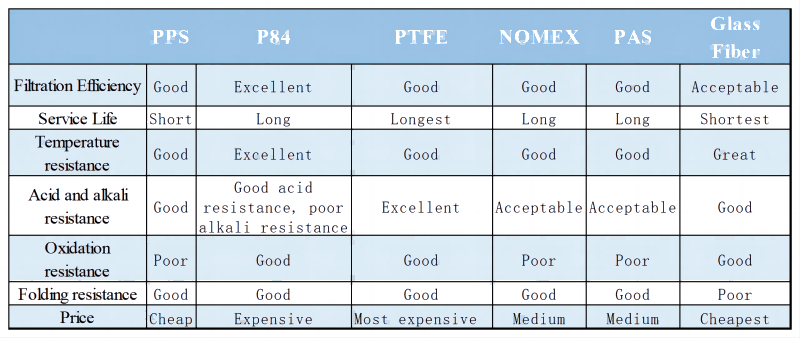

The filtering effect of bag filters is achieved through filtering materials. Different filtering effects can be achieved by equipping various types of filter bags with different properties, such as resistance to normal temperature(<130℃), resistance to high temperature(>130℃), corrosion resistance, water and oil repellent, fire and explosion prevention, and long service life (2-4 years). The changes and innovations in bag filter technology are closely related to the transformation of filter materials.

Currently, the main high-temperature filter fibers used for flue gas treatment domestically and internationally include PPS (polyphenylene sulfide), Nomex (aromatic polyamide), P84 (polyimide), PTFE (polytetrafluoroethylene), glass fibers, and PSA (polyphenylene sulfone) fibers. In practical applications, multiple fibers are often used in combination. Production processes include needle punching, surface coating, emulsion impregnation, etc., which can achieve surface filtration and gradient filtration effects. This not only improves the dust collection efficiency but also reduces pressure loss, facilitates dust cleaning, and saves energy consumption.

Introduction to Major High-Temperature Filter Media

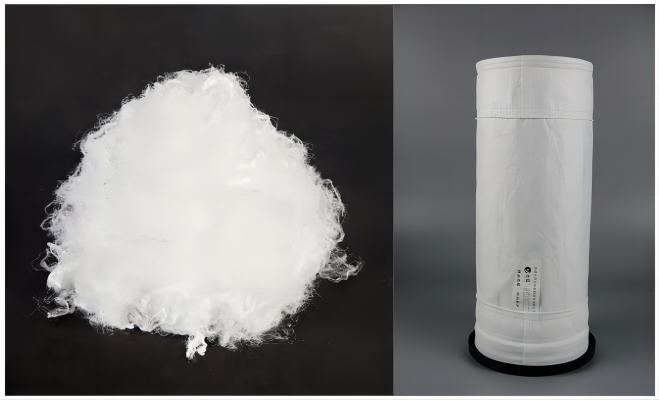

1. Polyphenylene Sulfide (PPS) - The most widely used high-temperature filter material

Polyphenylene sulfide fiber, with stable chemical properties, a high melting point (285°C), and excellent heat resistance. It also exhibits outstanding flame retardant, chemical resistance, and stability. It is mainly used in pulse bag filters for municipal waste incinerators, utility boilers, coal-fired boilers, hospital incinerators, and co-generation boilers. PPS is the most widely used high-temperature filter material.

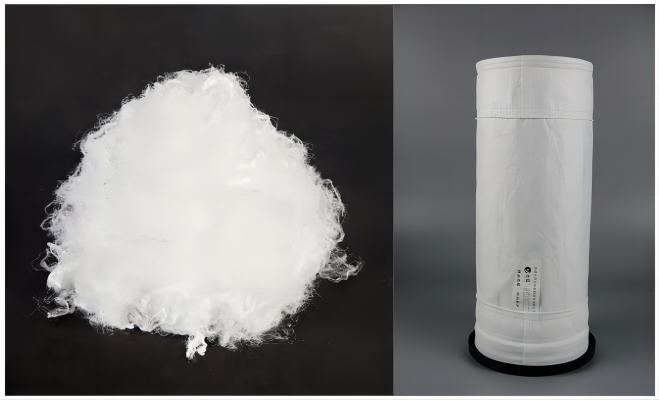

PPS fiber & PPS filter bag

From a global perspective, in 2012, PPS was mainly used in the automotive field, with 33% consumed in Japan and 50% consumed in Europe. In China, the consumption structure is primarily focused on environmental protection industries (filter bags), accounting for about 30%, followed by automotive components and the electronics/electrical industry.

2. Polyimide Fiber (P84) - The highest temperature-resistant dust removal material

Polyimide fiber, also known as aromatic polyimide fiber, is a high-performance fiber obtained by polymerizing pyromellitic dianhydride and aromatic diamine to form polyamide acid prepolymer, followed by solution spinning.

Polyimide fiber, originally developed by Lenzing AG in Austria, is commercially known as "P84." This monopolistic product is now owned by Evonik Industries in Germany and is mainly used in dust removal bags, earning it the nickname "Golden Silk"

P84 fiber P84 filter bag

Polyimide fiber has excellent comprehensive properties, including high temperature resistance, good filtration performance, and resistance to acid and alkaline substances. It can be used in high-temperature environments such as cement kiln tails, waste incineration, and power plants.

In addition, polyimide fiber products have a unique fiber structure - irregular leaf-shaped cross-sections, which increase the surface area by 80% compared to regular circular cross-sections. This brings two major advantages:

- Enhanced dust capture capability;

- The irregular fiber cross-sections naturally curl due to different internal stress levels and uneven distribution, providing strong entanglement force. Therefore, adding polyimide fiber to glass fiber composite needle-punched felts prevents easy shedding of the felt layer even at higher wind speeds.

You can also directly consult our sales engineers for free consultation services regarding your dust collection and denitrification projects.

↓ ↓ ↓ ↓ ↓

Contact us now!

3. Polytetrafluoroethylene (PTFE) Fiber - The best corrosion-resistant dust removal material

Polytetrafluoroethylene fiber, also known as "PTFE" or "fluoro fiber" in China. It was first developed by DuPont in 1953 and achieved industrial production in 1957. Polytetrafluoroethylene fiber is a synthetic fiber made from polytetrafluoroethylene raw material through spinning or film production, followed by cutting or staple fiber processing. Currently, there are four main production methods for polytetrafluoroethylene fiber, including emulsion spinning and paste extrusion spinning.

PTFE fiber PTFE filter bag

Polytetrafluoroethylene fiber inherits many advantages of polytetrafluoroethylene, such as excellent chemical stability, a wide range of operating temperatures, resistance to atmospheric aging, radiation resistance, and low permeability. It is mainly used as high-temperature dust filter bags, filter media resistant to strong corrosive gases or liquids, filler materials for pumps and valves, sealing tapes, self-lubricating bearings, reinforcing materials for alkaline full-fluoride ion exchange membranes, and rocket launch tower covers.

There are two forms of polytetrafluoroethylene dust filter bags: one is where polytetrafluoroethylene fibers are coated on other filter materials (such as PPS fibers, P84 polyimide fibers, glass fibers, etc.) to form a base cloth, and the other is where both the coating and base cloth are made of polytetrafluoroethylene fibers and processed into needle-punched felts. The performance of 100% polytetrafluoroethylene fiber filter bags is superior. Despite their excellent performance, the relatively high price of polytetrafluoroethylene fibers is a barrier to their widespread promotion.

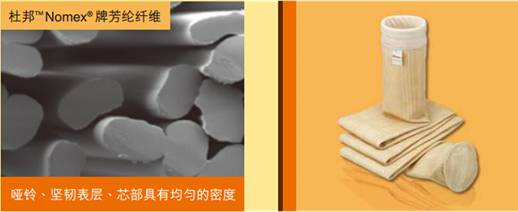

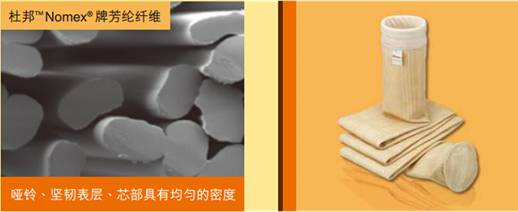

4. Nomex Fiber - The most widely used dust removal material

Nomex (Aramid) fiber is a high-performance synthetic fiber initially developed by DuPont. It possesses excellent properties such as high strength, high modulus, high temperature resistance, acid and alkali resistance, lightweight, and heat resistance. It finds wide applications in various fields. Currently, commercially available aramid varieties include meta-aramid and para-aramid, as well as a small amount of modified products such as aramid II and aramid III.

NOMEX fiber NOMEX filter bag

Meta-aramid exhibits high temperature resistance, flame retardant, and insulation performance. It is mainly used in high-temperature protective clothing, electrical insulation, and high-temperature filtration. Para-aramid, on the other hand, is primarily utilized for its high strength and modulus properties in personal protection, bulletproof armor, mechanical rubber products, high-strength ropes, and asbestos substitutes.

The high-temperature dust removal field is the main consumption market for meta-aramid. However, due to its cost-effectiveness compared to glass fiber and PPS, the market share of aramid fiber in the high-temperature filtration industry is only around 5%. One outstanding characteristic of aramid fiber filter bags in high-temperature applications is their extremely low shrinkage rate, maintaining a 1% shrinkage rate even after 1000 hours of use at 250°C.

5. Polyarylsulfone Fiber (PES) Introduction

Polyarylsulfone fiber belongs to the para-aramid series, scientifically known as polyphenylsulfone diphenylamine fiber. It is an aromatic polyamide fiber with sulfone groups (-SO2-) on the polymer backbone, making it a terpolymer.

PES filter bag

Polyarylsulfone fiber is an excellent material for manufacturing filter bags for baghouse dust collectors. It exhibits good heat resistance and excellent stability against thermal oxidation aging. It has low thermal shrinkage, maintains good dimensional stability, and possesses excellent acid resistance. It can be used for long periods at high temperatures and is particularly suitable for high-temperature filtration media.

Additionally, it is relatively cheaper compared to P84, PPS, and Nomex. The friction coefficient of polyarylsulfone fiber is low, making the resulting filter bags easy to clean. Its high temperature resistance allows it to be thermally bonded with PTFE (curing temperature of 260°C) to produce effective and stable laminated filter media.

6. Fiberglass - The most economical high-temperature filter material

Fiberglass is a traditional filter material and the most widely used filter material in medium to high-temperature flue gas filtration. Glass fibers can be classified into two main categories based on their glass composition: C-glass (alkali-containing) and E-glass (alkali-free) filter materials.

Fiberglass and Fiberglass filter bag

Fiberglass exhibits excellent high-temperature resistance and can operate for long periods under temperature conditions of 260°C (C-glass) / 280°C (E-glass). They can withstand instantaneous temperatures of up to 350°C. With high strength and low elongation, glass fibers have higher tensile strength than other natural and synthetic fibers. They also possess excellent corrosion resistance, except for corrosion by hydrofluoric acid. The smooth surface of glass fibers results in low filtration resistance, facilitating dust removal.

They are non-combustible and do not deform. Glass fibers treated with different surface agents have advantages such as softness, smoothness, hydrophobicity, anti-condensation, and low shrinkage. Glass fibers have outstanding dimensional stability, high tensile strength, strong corrosion resistance, smooth surface, air permeability, ease of dust cleaning, and good chemical stability. Due to their low cost, when cost is a priority for users, dust collection equipment manufacturers also use glass fibers for pulse bag filters.

You can also directly consult our sales engineers for free consultation services regarding your dust collection and denitrification projects.

↓ ↓ ↓ ↓ ↓

Contact us now!